The Miss Molly I Adventures - part one |

|

This is the first part of the story of our adventures with the junk-rigged, ferro-cement boat Miss Molly I. The complete story is slowly but surely developing into several chapters and will take a while to tell, so will gradually unfold as and when I get time to add to it. From my point of view, it was a great time and I hope to tell the story in its fullness to try to do it justice.

The start of it all

It's difficult to know where the story really starts. If it began one dark night on a weekend out from uni, paddling up and down the Cowes river in a cheap plastic toy inflatable dinghy looking for my mate's boat that the harbourmaster had thoughtfully moved, but not told him about; or breaking the top of the mast clean off in the same boat whilst crossing from Brittany to Poole; or whether it began repairing damaged woodwork on Tai Mo Shan - the boat in the Mama Mia film - in Turkey; or even working long hours for an Austrian boat charter company also in Turkey, trying to keep an aging and much-chartered fleet in service before being abruptly sacked for apparently being "too expensive". All of these played a role in leading up to the start of this story, but I guess Karin and I deciding to head over to Canada and see what that would bring is really where it all began.

We started just before Christmas, visiting friends of hers in Waterloo, headed down to Toronto, then Montreal, spent a week or so in the brilliant ex-jail youth hostel in Ottawa, before joining a car-share to drive the long way across, on frozen roads, through seriously sub-zero temperatures (-44 deg was the lowest I saw on a digital readout sign), to Banff. A week or so later, we took the bus from snow-covered Banff to sunny, kids-on-rollerblades-in-sunglasses-and-shorts, Vancouver.

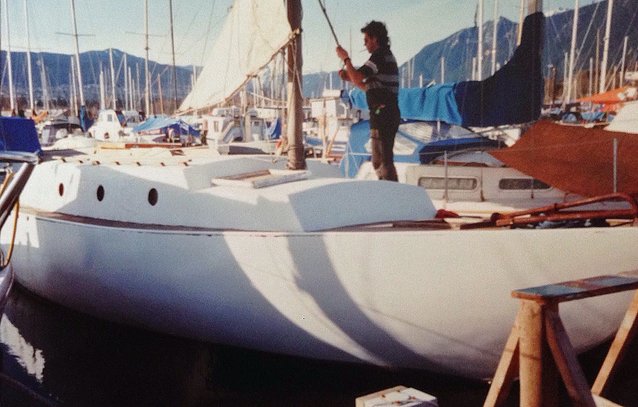

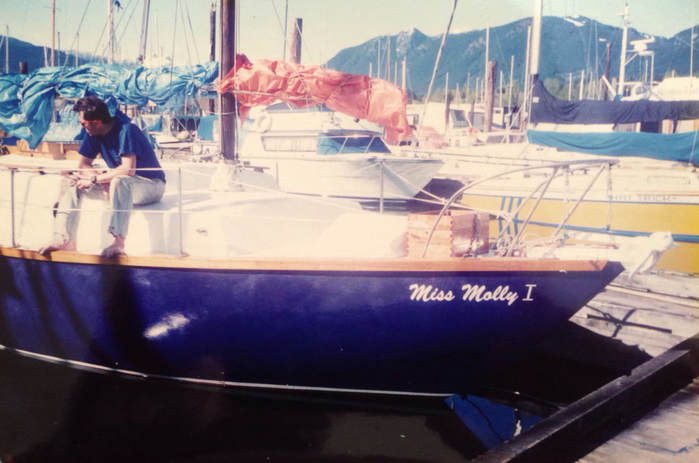

In early 1995, bored and with a wad of cash burning a hole in my pocket, I happened to spy a notice in the Vancouver evening newspaper advertising a sailboat for sale. A phone call and a few hours later, I was a good bit of that cash lighter and the owner of a rather dilapidated 32ft junk-rigged, ferro-cement boat, which would bring an end to my boredom and any remnant of cash I might possess, but also lead to new friends, horizons, experiences, a whole lot of learning, and eventually, children :-O

We started just before Christmas, visiting friends of hers in Waterloo, headed down to Toronto, then Montreal, spent a week or so in the brilliant ex-jail youth hostel in Ottawa, before joining a car-share to drive the long way across, on frozen roads, through seriously sub-zero temperatures (-44 deg was the lowest I saw on a digital readout sign), to Banff. A week or so later, we took the bus from snow-covered Banff to sunny, kids-on-rollerblades-in-sunglasses-and-shorts, Vancouver.

In early 1995, bored and with a wad of cash burning a hole in my pocket, I happened to spy a notice in the Vancouver evening newspaper advertising a sailboat for sale. A phone call and a few hours later, I was a good bit of that cash lighter and the owner of a rather dilapidated 32ft junk-rigged, ferro-cement boat, which would bring an end to my boredom and any remnant of cash I might possess, but also lead to new friends, horizons, experiences, a whole lot of learning, and eventually, children :-O

The earliest picture I have of Miss Molly I

I'm a boat owner!

Being now the proud owner of a sailing vessel, the immediate problem was what to do with her. I needed to find an affordable mooring, preferably somewhere in the Vancouver area. Somebody (I think the previous owner) suggested I try my luck with the marvellously named Mosquito Creek Marina, and so we fired up the trusty, rusty Volvo Penta MD1, putt putted over to North Van and Mosquito Creek, parked in an empty slot, wandered up to the office, and indeed were allowed to stay for a reasonable fee.

Mosquito Creek proved to be the perfect marina for us. It sits on land owned by the Squamish Nation and is run by them; a good number of native Americans (Canadians?) live in houses on site. It offered us at least a glimpse into Squamish Nation life, it was affordable, had good haul-out facilities and hard standing, the community was friendly and tolerant of builders/renovators, and perhaps most of all, the brilliant Popeye's sailors market was right next door. I think I can safely say that without Mosquito Creek and Popeye's we would never have succeeded in this project.

Mosquito Creek proved to be the perfect marina for us. It sits on land owned by the Squamish Nation and is run by them; a good number of native Americans (Canadians?) live in houses on site. It offered us at least a glimpse into Squamish Nation life, it was affordable, had good haul-out facilities and hard standing, the community was friendly and tolerant of builders/renovators, and perhaps most of all, the brilliant Popeye's sailors market was right next door. I think I can safely say that without Mosquito Creek and Popeye's we would never have succeeded in this project.

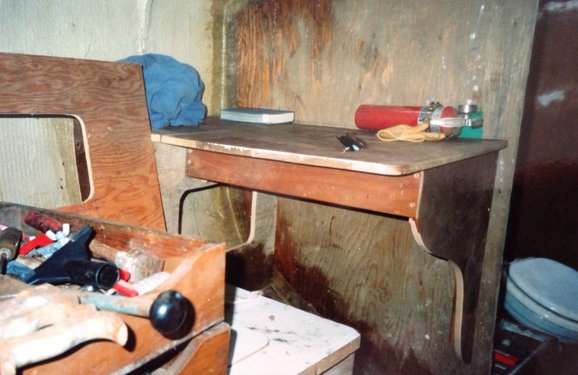

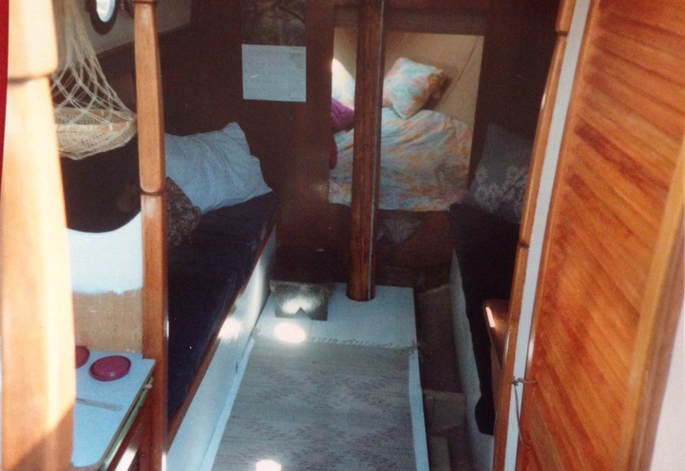

Down below was a bit of a mess

Sadly, I don't have many photos of the original condition of the boat. She had apparently been at anchor or on a mooring off of Nanaimo on Vancouver Island for quite a while. She was equipped in such a manner that it was possible to live on her in a basic kind of way, and she had obviously been brought across to Vancouver on the mainland in order to be sold, and so was also obviously capable of some maritime manoeuvres. She was fairly full of boxes and tubs of this and that, most of it in less than pristine condition, and there was a distinct smell of old diesel and dirty bilges permeating everywhere. I remember an over-large navigation table filling about half of the starboard living area, a simple galley with old pub hand pumps for fresh and salt water - the salt water one being seized as I suspect such pumps are not designed to cope with salt water. An egg-shaped hole in the main forward bulkhead led to a platform in the bows where various pieces of equipment were stored - a lot of junk, but including a very nice 1 inch anchor rode and a 45lb fisherman's anchor. But, it was easy to see that the accommodation had potential. With a bit of work, she could be made into a very comfortable liveaboard for 2 people.

The engine room (note oil pressure gauge tidily dangling from under the galley sink!)

The rebuild

But, I had been bored; I had a small amount of money left over; there were some tools on board; I was in a marina where boatowners lucky enough to be wealthier than me threw perfectly repairable or useable things in the skip at the top of the dock; I was in a city where house demolition (demo) sales happened several times every week and which were a wonderful source of materials - especially wood; there was a boat yard just a short walk away, also with scrap bits and pieces laying around; and, as I was very soon to discover, Popeye's boat market just around the corner.

Popeye's was God's gift to budget refitters. It was a medium-sized, dark, dingy, warehouse-type place, with high shelves packed full of just about anything you could imagine of a vaguely boaty nature - mostly secondhand. But best of all, it ran on a Dutch auction basis. For the uninitiated, this is a wonderful system whereby anybody can place an item there for sale. Items begin at a named price (set by the seller) and then the price goes down by a certain percentage every week if the item is not sold. Thus, a goodly number of forgotten or neglected items could be had for a dollar, but it did involve some serious gambling on desirable items. You had to decide just how much you were willing to pay and wait until the price dropped to that amount, desperately hoping that no one else would buy it betweentimes.

So, I got stuck in. The first job was basically to strip the entire interior out, with the exception of the main bulkheads and the bulkhead between the saloon and galley. All materials that were taken out were saved in an unsightly stack in the cockpit and on the coachroof and were reused as much as possible. We (Karin and I) then painted the inside of the hull a delightful sand colour. It was then time to start refitting. The starboard settee/sea berth was one of the first items to go in. A new plywood bulkhead was fitted about 2 feet aft of this, where the new nav table would go - the idea being that you could sit on the end of the settee to use the nav table, freeing up space aft of this new bulkhead for a toilet/sink/shower facility (head).

Popeye's was God's gift to budget refitters. It was a medium-sized, dark, dingy, warehouse-type place, with high shelves packed full of just about anything you could imagine of a vaguely boaty nature - mostly secondhand. But best of all, it ran on a Dutch auction basis. For the uninitiated, this is a wonderful system whereby anybody can place an item there for sale. Items begin at a named price (set by the seller) and then the price goes down by a certain percentage every week if the item is not sold. Thus, a goodly number of forgotten or neglected items could be had for a dollar, but it did involve some serious gambling on desirable items. You had to decide just how much you were willing to pay and wait until the price dropped to that amount, desperately hoping that no one else would buy it betweentimes.

So, I got stuck in. The first job was basically to strip the entire interior out, with the exception of the main bulkheads and the bulkhead between the saloon and galley. All materials that were taken out were saved in an unsightly stack in the cockpit and on the coachroof and were reused as much as possible. We (Karin and I) then painted the inside of the hull a delightful sand colour. It was then time to start refitting. The starboard settee/sea berth was one of the first items to go in. A new plywood bulkhead was fitted about 2 feet aft of this, where the new nav table would go - the idea being that you could sit on the end of the settee to use the nav table, freeing up space aft of this new bulkhead for a toilet/sink/shower facility (head).

The new starboard settee under construction

The nav table fixed to a newly installed bulkhead separating the saloon from the head. You sit on the end of the starboard settee to work at the nav table. Also note storage underneath nav table between settee and bulkhead.

The wash facilities in an early stage of construction

An early idea was to convert the storage area in the bows to a double berth in the forepeak. Using scrap wood and a couple of demo sale reclaimed flooring plywood sheets, I rebuilt the platform with lift out panels to access the storage underneath. I also blocked off a throughhull where a toilet had been attached and built a new opening hatch with perspex panels to increase the sense of space in there and let a bit of light in.

My new hatch - still unvarnished

Shelves were built either side in the forepeak for clothes storage and we later added hanging storage nets made from top quality fishing netting after we discovered a proper working fisherpersons' supply store which sold such things at working fisherpersons' prices :-) (we also bought oilskin trousers there, which served us very well later on and I still have to this day)

Karin varnishing shelves in the forepeak

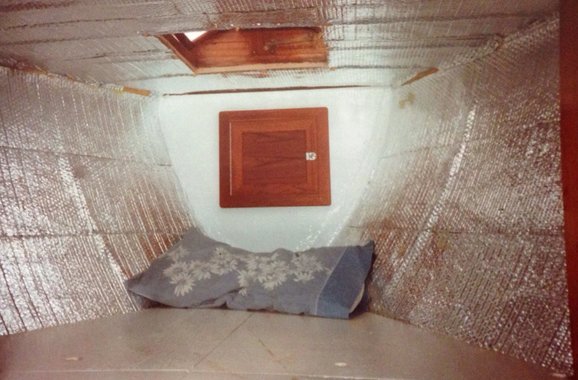

Another new bulkhead was fitted at the pointy end of the forepeak with a lovely teak hatch in it (a Popeye's bargain) and any part of the inside of the hull that was above storage level, (i.e. above the forward berth, above the settee backs, above the galley worksurfaces) was lined out with shiny foil-coated bubble wrap insulation material. This gave the inside a delightful spaceship feel until we covered that again with grey imitation leather vinyl.

Spaceship or forepeak?

While all this was going on, we were living in an attic on the other side of town. When I say an attic, it was literally an attic. It had a floor, but otherwise it wasn't built out as living space at all. We made up a bed from something (a pile of blankets?) and basically just slept there. Consequently, we were rather keen to move onto the boat as soon as possible - it would also save us the rent on the attic. This we did at the earliest possible stage. I remember some of the floorboards were missing so you had to tread carefully, but we had sleeping space, somewhere to sit, basic washing facilities and a functioning, if incomplete, galley.

The galley - still under construction, but we're living aboard by this stage

I had fitted a U-shaped galley with a foot pump for salt water and one of the old pub hand pumps for fresh water. I picked up 2 ten gallon water tanks from Popeye's that fitted perfectly in the bilge and so plumbed them to the hand pump in the galley and another foot pump in the head. We filled the tanks by lifting a floorboard and pouring water in from jerry cans.

I also invented a gimballing system for our camping gas two burner stove. I mounted it in a pivoted wooden tray, underneath which was a fixed wooden box holding a large lead weight. It ensured the stove stayed level as the boat rocked and worked quite well until I picked up another Popeye's bargain of a Dickinson Bristol diesel stove, which fitted in the space perfectly and duly made my invention redundant (the stove did get used again in Mexico, where it was a bit hot down below with the Dickinson running, but my brilliant gimballing device was never used again :-()

Living aboard brought us into contact with more of the local community. The Davitts - Craig and Ron were early acquaintances. They were a lively pair, of Scottish extraction, born and bred in Canada. In fact, when I first parked in a slot on the dock in Mosquito Creek, it turned out to be Craig's slot, and, as you might imagine, he wasn't best pleased when he returned from his cruise to find Miss Molly I parked there. He was fair though - we went up to the office together and we were given another mooring. Later, when he went off for a longer cruise in his sailboat, we sub-letted Craig's space. I also remember a delightful evening when we went out in Craig's boat to watch the Vancouver Celebration of Light fireworks from the perfect viewing spot on the water.

His brother Ron became a regular evening visitor to Miss Molly I. Always with a six-pack of beer and a guitar in hand, he'd come by and we'd spend the evening drinking, playing guitar and singing. He played the essential role of introducing us to the music of Jimmy Buffett - I remember Ron's renditions of "A Pirate Looks At 40" particularly well. Largely unknown in Europe (at least to us!), Jimmy Buffett's music played a central cultural role in our subsequent travels on the west coast, becoming a recurring theme; I still play and listen to it fondly from time to time.

As things progressed, it started to get more and more comfortable on board. We bought some foam and Karin and her mate Evelyn (Karin had previously au paired for a year in Vancouver and so knew a few people round and about) sewed cushion covers, The inside was taking shape. Later, as winter approached, the new Dickinson diesel stove was a blessing, keeping things cosy below decks. In cold weather, it could be left permanently running, and it was a real treat to wake up in the morning, put the kettle and a pot of porridge on and then get back in bed for the 20 minutes or so it took to boil the kettle and cook the porridge. The head was finished, complete with homemade holding tank. I mentioned a shower earlier. This was of the simplest possible variety, but it functioned. We had one of those black bag solar shower things. It sat outside on the coachroof and the hose with the showerhead was handed through the head porthole. The water in the bag never got warm of its own accord in Canada, but could be filled nicely with water from the kettle, mixed with cold water to give the desired temperature. A drain in the head floor ran into a rubber hose that led to a 5 litre plastic container in the bilge. This, obviously, had to be emptied after each shower.

I had fitted a longitudinal bulkhead either side of the motor to give us more storage space. A small crawl-through door opened immediately behind the toilet, giving access to a space about 5 feet long that housed the holding tank and made a nice wet locker, including storage for some tatty old life vests that we would be obliged to take along, but never intended to wear. We had bought 2 self-inflating life vests that doubled as harnesses and would be wearing them when we finally set off cruising, but Canadian and US American regulations didn't accept them as being suitable as safety equipment, hence the tatty ones in the wet locker that would fulfil the safety equipment requirements. The space formed by the bulkhead on the port side of the engine was accessed through the lazarette and was where we stored longer items and spare pieces of wood etc. The easily accessed part of the lazarette, directly under and to either side of the hatch, stored ropes, fenders, spare anchors and chain, four 10 litre diesel jerry cans and five 10 litre water jugs.

There was one area that bothered me a bit. In the bilge, a part of the inside of the keel had been built as a water tank. It had a plywood top fibreglassed in place with a circular inspection cover in it. The whole thing didn't smell too good and had obviously been contaminated with oily bilge water and I had emptied it out early on in the build. I had removed the top and, once it had dried, painted the inside of what had been the tank, but there were some seeping rusty spots that I really didn't like. At one point, I had scraped them off a bit and coated them with some epoxy, but the seeping never completely stopped. I wasn't really at ease and inspected them regularly.

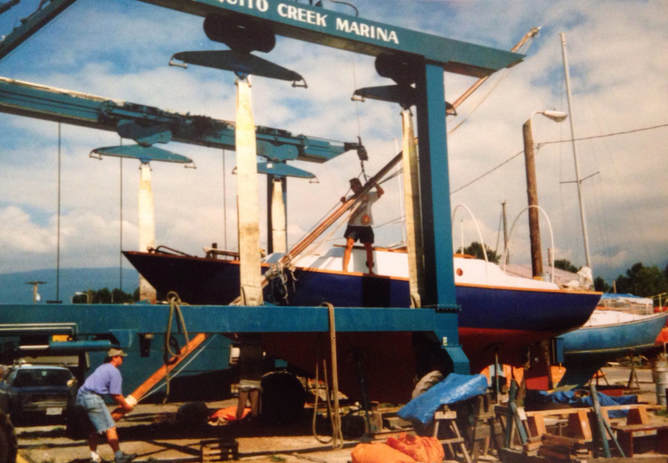

Anyhow, work down below was nearing completion and it was time to haul out. As previously mentioned, Mosquito Creek was well suited to haul out work. They had a travelift, crane and plenty of hard standing in their yard. Liveaboards were permitted in the hard standing. We arranged an appointment and paid the dues.

I also invented a gimballing system for our camping gas two burner stove. I mounted it in a pivoted wooden tray, underneath which was a fixed wooden box holding a large lead weight. It ensured the stove stayed level as the boat rocked and worked quite well until I picked up another Popeye's bargain of a Dickinson Bristol diesel stove, which fitted in the space perfectly and duly made my invention redundant (the stove did get used again in Mexico, where it was a bit hot down below with the Dickinson running, but my brilliant gimballing device was never used again :-()

Living aboard brought us into contact with more of the local community. The Davitts - Craig and Ron were early acquaintances. They were a lively pair, of Scottish extraction, born and bred in Canada. In fact, when I first parked in a slot on the dock in Mosquito Creek, it turned out to be Craig's slot, and, as you might imagine, he wasn't best pleased when he returned from his cruise to find Miss Molly I parked there. He was fair though - we went up to the office together and we were given another mooring. Later, when he went off for a longer cruise in his sailboat, we sub-letted Craig's space. I also remember a delightful evening when we went out in Craig's boat to watch the Vancouver Celebration of Light fireworks from the perfect viewing spot on the water.

His brother Ron became a regular evening visitor to Miss Molly I. Always with a six-pack of beer and a guitar in hand, he'd come by and we'd spend the evening drinking, playing guitar and singing. He played the essential role of introducing us to the music of Jimmy Buffett - I remember Ron's renditions of "A Pirate Looks At 40" particularly well. Largely unknown in Europe (at least to us!), Jimmy Buffett's music played a central cultural role in our subsequent travels on the west coast, becoming a recurring theme; I still play and listen to it fondly from time to time.

As things progressed, it started to get more and more comfortable on board. We bought some foam and Karin and her mate Evelyn (Karin had previously au paired for a year in Vancouver and so knew a few people round and about) sewed cushion covers, The inside was taking shape. Later, as winter approached, the new Dickinson diesel stove was a blessing, keeping things cosy below decks. In cold weather, it could be left permanently running, and it was a real treat to wake up in the morning, put the kettle and a pot of porridge on and then get back in bed for the 20 minutes or so it took to boil the kettle and cook the porridge. The head was finished, complete with homemade holding tank. I mentioned a shower earlier. This was of the simplest possible variety, but it functioned. We had one of those black bag solar shower things. It sat outside on the coachroof and the hose with the showerhead was handed through the head porthole. The water in the bag never got warm of its own accord in Canada, but could be filled nicely with water from the kettle, mixed with cold water to give the desired temperature. A drain in the head floor ran into a rubber hose that led to a 5 litre plastic container in the bilge. This, obviously, had to be emptied after each shower.

I had fitted a longitudinal bulkhead either side of the motor to give us more storage space. A small crawl-through door opened immediately behind the toilet, giving access to a space about 5 feet long that housed the holding tank and made a nice wet locker, including storage for some tatty old life vests that we would be obliged to take along, but never intended to wear. We had bought 2 self-inflating life vests that doubled as harnesses and would be wearing them when we finally set off cruising, but Canadian and US American regulations didn't accept them as being suitable as safety equipment, hence the tatty ones in the wet locker that would fulfil the safety equipment requirements. The space formed by the bulkhead on the port side of the engine was accessed through the lazarette and was where we stored longer items and spare pieces of wood etc. The easily accessed part of the lazarette, directly under and to either side of the hatch, stored ropes, fenders, spare anchors and chain, four 10 litre diesel jerry cans and five 10 litre water jugs.

There was one area that bothered me a bit. In the bilge, a part of the inside of the keel had been built as a water tank. It had a plywood top fibreglassed in place with a circular inspection cover in it. The whole thing didn't smell too good and had obviously been contaminated with oily bilge water and I had emptied it out early on in the build. I had removed the top and, once it had dried, painted the inside of what had been the tank, but there were some seeping rusty spots that I really didn't like. At one point, I had scraped them off a bit and coated them with some epoxy, but the seeping never completely stopped. I wasn't really at ease and inspected them regularly.

Anyhow, work down below was nearing completion and it was time to haul out. As previously mentioned, Mosquito Creek was well suited to haul out work. They had a travelift, crane and plenty of hard standing in their yard. Liveaboards were permitted in the hard standing. We arranged an appointment and paid the dues.

In the travelift

Mast out

Dirty bottom

On haulout, the first thing that was obvious was that the bottom hadn't been cleaned for quite a while. She was covered in growth, barnacles and other molluscs. A quick initial scrape, led to a few pieces of concrete flaking off the very bottom of the keel, and initial inspection revealed a couple of small rusty patches higher up that would certainly require further investigation.

An initial scrape led to some flaking of concrete at the bottom of the keel

And there were some rusty patches higher up that I really didn't much care for

The travelift drove her into the yard and she was duly settled of some wooden blocks and props, we got a ladder from somewhere and began getting used to life on the hard.

As I mentioned earlier, there was quite a community around Mosquito Creek. One couple that we got to know very well and spent a fair bit of time with were Richard and Danielle. He, like me, was an Englishman - a trained chef, if I remember correctly - and she hailed from Australia. They had also bought a ferro-cement sailboat - a converted wooden lifeboat hull that had been ferro-cemented over. They had their boat in a boatshed on the hard and were undertaking a complete refit. They had a couple of woodworking machines standing in their boatshed and were also already fairly well connected with people in the vicinity, both of which proved quite useful. It was certainly good to chat to them about boats and life in general in those times when a break from boatwork was needed.

After giving the boat a thorough scraping below the waterline, I decided to probe deeper into those ominous rusty patches. I probed and found soft concrete. Obviously, anything that was soft had to be removed so that these blisters could be properly filled and repaired. I started digging out the soft stuff. Before I knew it, I'd gone straight through the hull from the outside, into the former watertank on the inside. Not good! But it had to go. I carried on scraping and digging and chipping - anything that wasn't solid concrete. At the end of the morning, when I was finally convinced I'd got rid of all the soft stuff and was down to purely solid, sound concrete, the picture was heartbreaking. I can clearly remember stepping back, looking at the state of the boat and saying to Karin, "We're fucked". - It actually stresses me now, years later, just writing about it.

As I mentioned earlier, there was quite a community around Mosquito Creek. One couple that we got to know very well and spent a fair bit of time with were Richard and Danielle. He, like me, was an Englishman - a trained chef, if I remember correctly - and she hailed from Australia. They had also bought a ferro-cement sailboat - a converted wooden lifeboat hull that had been ferro-cemented over. They had their boat in a boatshed on the hard and were undertaking a complete refit. They had a couple of woodworking machines standing in their boatshed and were also already fairly well connected with people in the vicinity, both of which proved quite useful. It was certainly good to chat to them about boats and life in general in those times when a break from boatwork was needed.

After giving the boat a thorough scraping below the waterline, I decided to probe deeper into those ominous rusty patches. I probed and found soft concrete. Obviously, anything that was soft had to be removed so that these blisters could be properly filled and repaired. I started digging out the soft stuff. Before I knew it, I'd gone straight through the hull from the outside, into the former watertank on the inside. Not good! But it had to go. I carried on scraping and digging and chipping - anything that wasn't solid concrete. At the end of the morning, when I was finally convinced I'd got rid of all the soft stuff and was down to purely solid, sound concrete, the picture was heartbreaking. I can clearly remember stepping back, looking at the state of the boat and saying to Karin, "We're fucked". - It actually stresses me now, years later, just writing about it.

"We're fucked"

Also from the inside

Clearly, I'd been very naive and had made the absolute beginners mistake of buying a boat without hauling it out to inspect it below the waterline. Make no mistake, this is something I would never do again! My world was rocked and for a while, after all that hard work to make her a pleasant liveaboard inside, I nearly threw in the towel. It's hard to remember clearly - I was certainly dazed - I remember people coming by to look at her and offering sympathies. The former owner came by and saw it all and muttered something like "I never knew..." I think I probably had a few (British understatement!) drinks and slept on it.

And then, as is always the case in challenging times, the engineer in me kicked in and I started to think of ways to repair the hull. What remained of the hull was all solid ferrocement. The cross-sectional shape of the hull was wider at the top and narrower at the bottom. there were cross-braces of solid ferrocement every 3 feet or so in the bilge. There was a ferrocement beam, in good order, along the bottom of the keel, soundly connecting the front of the keel to the back. All I had to do was to replace the missing rebar and wire mesh, fill the former water tank with concrete of the correct sand/cement ratio and put another inch or two of concrete all through the rest of the bilge on top of the existing keel that would cover and fill almost all of the holes with a concrete "wedge" that couldn't possibly fall out and that would tie everything solidly together.

And then, as is always the case in challenging times, the engineer in me kicked in and I started to think of ways to repair the hull. What remained of the hull was all solid ferrocement. The cross-sectional shape of the hull was wider at the top and narrower at the bottom. there were cross-braces of solid ferrocement every 3 feet or so in the bilge. There was a ferrocement beam, in good order, along the bottom of the keel, soundly connecting the front of the keel to the back. All I had to do was to replace the missing rebar and wire mesh, fill the former water tank with concrete of the correct sand/cement ratio and put another inch or two of concrete all through the rest of the bilge on top of the existing keel that would cover and fill almost all of the holes with a concrete "wedge" that couldn't possibly fall out and that would tie everything solidly together.

Mesh and rebar going back in. Also rebar ties between cross-braces and in the former water tank

Ready for new keel casting. The hole top left wouldn't be covered by the extra keel concrete - that would have to be just filled.

For those of you not au fait with the wonders of ferrocement boat construction, the basic system of hull construction is this: An "armature" is constructed of fairly small diameter (1/4 inch, approx 7mm) steel bar, with shaped bars running in the direction of traditional frames (the y-axis) every 18 inches (45cm) or so, and longitudinal bars (stringers, the x-axis) every 2 inches (5cm) or so. These are all assembled and wired together to form a bent steel bar 3D form of the boat, and then the entire structure is covered with about 5 layers of steel wire mesh - preferably the sort with 1/2 inch (13mm) or so square holes - all wired to the steel bar armature. This is then all plastered with a 2:1 ratio, sand:cement concrete mix made with clean quartz sand and preferably type 5 portland cement. If the work is done well, there will be no voids in the finished hull and the outside hull will be beautiful and fair (sadly, as many were built by home builders, they are not all done well). The finished hull is about 1 inch (25mm) thick, with thicker parts where structurally necessary. Apparently a hull thus constructed will be lighter than a traditionally built wooden boat and it will certainly be immensely strong. I cut a couple of holes for through-hulls in Miss Molly I and it was quite a task - the concrete was extremely hard and the steel bars get in the way. The one essential thing with ferrocement boats is that steel and sea water should never come in contact with each other. If the steelwork starts to rust, it expands as it does so, splitting the concrete around it and so opening it up to further water intrusion and thus further corrosion. If sea water and steel never meet, there is no reason why a ferrocement boat hull shouldn't remain as an immensely strong structure for a very long time.

So, I'd replaced the missing steel bar parts and added a few more for luck and then wired 5 layers of 1/2 inch mesh to that, inside and outside (2 + 3). I procured some sacks of cement (couldn't get type 5, so had to make do with type 10) and some nice clean quartz sand. It was now time to start mixing. Richard and Danielle gallantly volunteered to help us on the day, and bright and early one summer's morning, we set to.

So, I'd replaced the missing steel bar parts and added a few more for luck and then wired 5 layers of 1/2 inch mesh to that, inside and outside (2 + 3). I procured some sacks of cement (couldn't get type 5, so had to make do with type 10) and some nice clean quartz sand. It was now time to start mixing. Richard and Danielle gallantly volunteered to help us on the day, and bright and early one summer's morning, we set to.

Richard and I mixing concrete the traditional way. Danielle can just be seen in the background on water supply duties. (Health and safety was a bit lax, you might notice!!)

We mixed on boards the way I'd been brought up to do. - The earliest job I can remember my dad doing was driving a Readymix concrete mixer truck. Whenever there was a load in the back that was surplus to requirements, the drivers were paid a bonus for getting rid of it somewhere. I know my dad did fairly well out of this by supplying at least one local farmer to gradually build a concrete driveway up to his farmyard, but some of the surplus also came home to us and we laid a concrete back yard and path down the entire length of our rather long and narrow garden. However, whenever small quantities of concrete were required at home, this is how my dad taught me to mix by hand - on boards, mixing the dry ingredients by turning them several times to get a homogeneous mix, forming a well, pouring in the required quantity of water and mixing it in gradually with shovels until an even, plastic mixture is achieved. (You could almost say I grew up with concrete, but as my dad was, and still is, a keen gardener, I also spent a fair bit of time helping him with my toy wheelbarrow to barrow trailer-loads of manure down the garden - concrete and manure, maybe!)

When the mix was ready, we filled it into buckets, lugged it up the ladder and poured it into the former tank and keel space from above. Karin then poked it with a piece of wood to get any air bubbles out and compact it nicely.

When the mix was ready, we filled it into buckets, lugged it up the ladder and poured it into the former tank and keel space from above. Karin then poked it with a piece of wood to get any air bubbles out and compact it nicely.

Filled! (Richard seems to be on stick-poking duties in this shot!)

Even with this quantity of concrete weighing it down, the wet concrete only oozes slowly for a short while through the layers of wire mesh wired to the armature, and so a nice smooth finish can be achieved by simply using a plasterer's trowel (or in our case, a homemade wooden float) to even this off as it oozes.

Finishing work in progress on the outside

The holes are gone!

Though I say so myself, the finished job really looked rather good. The hull was nice and smooth. We'd painted wet epoxy on all points where new concrete met old before filling the new concrete in, and this seemed to work well in providing a good bond between old and new. We had to wait several weeks for the concrete to cure to a workable level - it gave off a tremendous amount of heat, being positively hot to the touch in the early stages - but during this time, I sanded off the entire outside hull paintwork and prepared it for new, fitted a new propeller shaft bearing, and big end bearings and piston rings in the engine.

Primer/undercoat going on

I remember Karin and I thinking long and hard about choosing a suitable colour for the hull paint - asking various friends and acquaintances for their opinion, before settling on a darkish blue colour from the swatches provided by the good people at Devoe paints. We bought the 2-component epoxy-based marine paint from Devoe in Vancouver and applied it with a roller - 2 coats of undercoat/primer and 2 of topcoat. The deck and coachroof were painted white, which significantly reduced the heat adsorption and radiation of the deck (it had been aged-concrete grey and got too hot to walk on even in the Vancouver summer - it would have been totally unsuitable for southern latitude conditions). I began fitting a reclaimed wood (demo sale) mahogany toe rail/gunwale around the boat to cover and seal the deck/hull joint, which had been leaking and was unsightly. I also scraped and sanded the mast, made up a new masthead fitting from stainless steel, according to the specifications in Hasler and McLeod's wonderful Practical Junk Rig, fitted a masthead VHF antennae with the cable embedded in the mast, and saturated the entire mast in a mix of linseed oil and paraffin.

Paint and anti-fouling on. Mast going back in.

Afloat again

Back in the water, things were moving on apace. The toe rail was finished off with a mahogany cap, sanded and varnished; a new mast boot was fashioned according to the guidelines in 'Practical Junk Rig'; I picked up a sturdy ex-working boat bow roller and fitted that on some teak blocks cut from some teak pieces I found in scrap in the boatyard; various cleats and fairleads were fitted - a large cleat forward to tie the anchor off (I'd picked up 180 ft of anchor chain from Popeye's at a decent price), a couple on the aft quarters for mooring purposes, 6 cleats on the coachroof for halyards, lazyjacks and the various other lines that help control a junk sail. The rigging was checked and lines, blocks and shackles renewed as necessary, and I fitted a main sheet traveller aft of the cockpit and a very nice double main sheet block with cam cleats on that. Popeye's supplied (well, I bought) a stainless bow fitting and later stainless stanchions were fitted to which rope 'lifelines' were attached.

Down below,things were getting a bit more comfy.

Down below, things were getting a bit more comfy. We'd varnished all of the hardwood and painted the softwood panels white; fiddles, doors and catches were fitted to keep things in place once at sea. I bought a sheet of 3/4 inch ply to make up the missing floorboards and got some very nice oak strip flooring from a demo sale that I laid on all of the cabin sole boards (varnished) and in the cockpit and on the lazarettte hatch (stripped), which made everything look quite fancy. We fitted nets and baskets where possible for storage, a secondhand VHF radio for communication, a second battery (one for the motor and one as a service battery) with all new wiring and switches throughout; a couple of electric reading lights were fitted above the settees and two oil lamps were fitted midships to give lighting options as necessary.

Oak strip going down in the cockpit area - A new cockpit drain was fitted subsequently

In fact, the order in which things occurred around this time is rather hazy - we did so much. Certainly new hardwood cleats were fitted on the cockpit combing in order to sheet off a light-airs foresail I'd picked up at Popeye's; the lazarette hatch was fitted with hinges and a screw-down catch to keep thing safe; the manual bilge pump was relocated to be useable from the cockpit and an electric one was fitted midships; a new cockpit drain was installed; the companionway was rebuilt with new secondhand teak stairs and a demo sale mahogany engine cover, all kept in place with brass bolts; I built and installed a box from recycled mahogany on the foredeck to house the anchor chain - I still don't like the idea of having some sort of opening in the deck or hull to store it in an anchor locker or otherwise below; new compasses were installed; new navigation lights were fitted; a stainless, gas rail barbeque was obtained; I adapted and fitted a stainless swim ladder; I built and fitted a homemade windvane; a rather old, and slighly out-of-date liferaft was bought (Popeye's again) and fitted in a holder on the coachroof forward of the mast; etc, etc, etc.

On 4th September we decided to take her out for a weekend - our first cruise in the boat since starting renovations. We viewed it very much as a test run and so decided to head inland, up past the Second Narrows Bridge, to the end of Indian Arm, a long fjord-like inlet. We set off about 9:30 in the morning and, after filling up with diesel at the fuel barge, we motored (no wind) up towards the bridge, arriving too early to avoid the out-going tide. After an initial attempt made it obvious that our mighty 7hp Volvo Penta wasn't going to get us through against the current, we waited half an hour and made it through on the second go. As we turned northwards up into Indian Arm, we picked up a bit of wind, hoisted sail and ran dead downwind at about 4 knots up the Arm. The junk sail worked beautifully dead downwind, with none of that dangerous jibing nonsense that other rigs suffer from. The only problem we experienced was that one of the bamboo battens that I'd fitted in a silly attempt at authenticity broke - clearly nowhere near strong enough. We anchored right up the end of the Arm, in about 17m of water, at about 16:00, and settled down to enjoy the tranquility - we were the only boat!

We stayed there the next day. I'd "found" a fibreglass dighy, virtually submerged and covered in weed somewhere in the vicinity of Mosquito Creek, had cleaned it up and we'd towed it behind with us on this trip. We did some longish rowing trips around the top of Indian Arm in the dinghy, lapping up the nature and general greenery. Then on 6th Sept., we headed back southwards, stopping off for lunch at Belcara Park, before motoring back in a very light noserly to Mosquito Creek.

The "found" dinghy got me into a bit of mild trouble later. One of the Squamish men, a boat owner and a bit of a player, claimed it belonged to him - it may well have done. I was obliged to buy it from him at a price that was rather high to my thinking, and as it was too big for us to get on board Miss Molly I and therefore useless for longer voyaging, I subsequently gave it a lick of paint and attempted to sell it at Popeye's to no avail. John, the owner of Popeye's gave me a few dollars for it in the end, when we were about to leave for good and I was desperate to get anything at all for it, and I bought a Sevylor Fish Hunter - which, despite being a cheap, crap inflatable dinghy, could be stored in the lazarette when not in use and survived everything we subsequently threw at it.

We spent the winter in Vancouver, finishing off bits and bobs on the boat and trying to get her cruising-ready. We had about a week of snow mid-winter, piled up on the coachroof, but were cosy on board with the Dickinson stove. We were getting ready to head off come springtime, so had a few parties and hung out with some of the lovely people we'd become friends with in Vancouver. We took a road trip up to Prince George to visit my old mate Ray (now an artist of some repute in the Vancouver area) - Ray and I had met in Turkey and had toured Egypt together - on the way back, after our ferry from Haifa had been cancelled and we'd been obliged to wait a week in a hostel in Tel Aviv, I met Karin (ain't life strange!)

Finally, we hauled out one more time for a quick inspection and to fit some new sacrificial anodes. The marvellous Craig Davitt supplied us with some sticky boat name and home port labels that he applied personally and then refused any payment for, the inspector from the Canadian boat registry office came out and inspected, and we were ready... well sort of!! (actually we still had quite a list of jobs to do, but decided to finish them off underway)

On 4th September we decided to take her out for a weekend - our first cruise in the boat since starting renovations. We viewed it very much as a test run and so decided to head inland, up past the Second Narrows Bridge, to the end of Indian Arm, a long fjord-like inlet. We set off about 9:30 in the morning and, after filling up with diesel at the fuel barge, we motored (no wind) up towards the bridge, arriving too early to avoid the out-going tide. After an initial attempt made it obvious that our mighty 7hp Volvo Penta wasn't going to get us through against the current, we waited half an hour and made it through on the second go. As we turned northwards up into Indian Arm, we picked up a bit of wind, hoisted sail and ran dead downwind at about 4 knots up the Arm. The junk sail worked beautifully dead downwind, with none of that dangerous jibing nonsense that other rigs suffer from. The only problem we experienced was that one of the bamboo battens that I'd fitted in a silly attempt at authenticity broke - clearly nowhere near strong enough. We anchored right up the end of the Arm, in about 17m of water, at about 16:00, and settled down to enjoy the tranquility - we were the only boat!

We stayed there the next day. I'd "found" a fibreglass dighy, virtually submerged and covered in weed somewhere in the vicinity of Mosquito Creek, had cleaned it up and we'd towed it behind with us on this trip. We did some longish rowing trips around the top of Indian Arm in the dinghy, lapping up the nature and general greenery. Then on 6th Sept., we headed back southwards, stopping off for lunch at Belcara Park, before motoring back in a very light noserly to Mosquito Creek.

The "found" dinghy got me into a bit of mild trouble later. One of the Squamish men, a boat owner and a bit of a player, claimed it belonged to him - it may well have done. I was obliged to buy it from him at a price that was rather high to my thinking, and as it was too big for us to get on board Miss Molly I and therefore useless for longer voyaging, I subsequently gave it a lick of paint and attempted to sell it at Popeye's to no avail. John, the owner of Popeye's gave me a few dollars for it in the end, when we were about to leave for good and I was desperate to get anything at all for it, and I bought a Sevylor Fish Hunter - which, despite being a cheap, crap inflatable dinghy, could be stored in the lazarette when not in use and survived everything we subsequently threw at it.

We spent the winter in Vancouver, finishing off bits and bobs on the boat and trying to get her cruising-ready. We had about a week of snow mid-winter, piled up on the coachroof, but were cosy on board with the Dickinson stove. We were getting ready to head off come springtime, so had a few parties and hung out with some of the lovely people we'd become friends with in Vancouver. We took a road trip up to Prince George to visit my old mate Ray (now an artist of some repute in the Vancouver area) - Ray and I had met in Turkey and had toured Egypt together - on the way back, after our ferry from Haifa had been cancelled and we'd been obliged to wait a week in a hostel in Tel Aviv, I met Karin (ain't life strange!)

Finally, we hauled out one more time for a quick inspection and to fit some new sacrificial anodes. The marvellous Craig Davitt supplied us with some sticky boat name and home port labels that he applied personally and then refused any payment for, the inspector from the Canadian boat registry office came out and inspected, and we were ready... well sort of!! (actually we still had quite a list of jobs to do, but decided to finish them off underway)

Getting there!